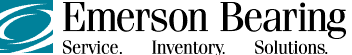

ABEC Rating Guide

The Annular Bearing Engineering Committee (ABEC) was founded over 50 years ago as a subset of the American Bearing Manufacturers Association (AMBA). It is the duty of this committee to establish acceptable tolerances related to the dimensional and running accuracy of all bearings. The tolerance level of a bearing is referred to as an ABEC rating

ABEC ratings have become the accepted industry standard for all ball and roller bearing tolerances, and as such, bearing manufacturers worldwide are required to have their products rated by ABEC. Once assessed, the rating is etched onto the bearing. Bearing tolerances are also regulated by equivalent ISO 492 and JIS B 1514 standards.

ABEC ratings act as a partial guide for consumers to make informed decisions about the types of bearings that may be best suited for their application, but do not provide knowledge of other essential properties. Therefore, this rating system is only one of several tools that should be used when determining appropriate bearing selection.

Types of ABEC Ratings

Types of ABEC Ratings

The ABEC rating system uses odd numbers—1, 3, 5, 7, 9—as classification ratings. The five distinct classifications are arranged in ascending order of tolerance. A higher rating signifies tighter tolerances higher precision, efficiency, and speed capabilities for the bearing. It should be noted that the rotational speed of a component is dependent on several other factors outside of the specific ABEC rating.

The ABEC scale and equivalent ISO 492 ratings are shown below:

- ABEC 1: ISO Class 6X

- ABEC 3: ISO Class 6

- ABEC 5: ISO Class 5

- ABEC 7: ISO Class 4

- ABEC 9: ISO Class 2

For example, on an ABEC 1 bearing with an outside diameter of less than 2 inches, the width of the outer ring can deviate within -0.0050 inches. However, for an ABEC 7 bearing of the same diameter, the width of the outer ring can deviate no more than -0.001 inches.

The committee tests two main factors to determine tolerance levels: dimensional accuracy and running accuracy. Dimensional accuracy includes physical bearing characteristics such as:

- Bore diameter

- Outer diameter

- Bearing width

- Allowable inner ring tapered deviation

- Shape error

Running accuracy, on the other hand, measures parameters related to inaccuracies such as axial runout, or inner and outer ring runout, among others.

How to Choose the Right ABEC Rating for Your Bearing

Choosing the right ABEC rating for your bearing application requires a sound understanding of what the ABEC scale represents. Most bearings sold belong to ABEC ratings 1 and 3, and perform very well. These bearings are on the middle end of the spectrum and are commonly found in non-precision applications such as automotive components, skateboards, electric motors, and gearboxes, among others.

Stricter tolerances are typically required in applications where bearings need to function at very high RPMs, or in equipment where accurate positioning is essential. For instance, products such as high-speed routers, where speeds can exceed 30,000 RPM, are referred to as high-precision, ultra-precision, and super or super-high precision.

In these cases, ABEC ratings of 7 or 9 are typically required. The fabrication of these higher-rated bearings requires more precise machining and extended production time. They also possess a significantly higher price point, often as much as five times higher than lower-rated bearings. Other applications that use bearings on the upper end of the ABEC scale include:

- Machine tools

- Aerospace components

- Robotics

- Medical devices and equipment

- Devices that must maintain high RPMs

It is important to note that while ABEC ratings can help determine bearing performance to a degree, several other factors need to be assessed when selecting a suitable bearing. The ABEC rating, for instance, does not consider material properties, impact resistance, side loading, lubrication, clearance, noise, and installation requirements.

As such, it is possible to observe a significant difference in performance between two similarly rated bearings in different environments. For similar reasons, there may also be situations where bearings with lower ABEC ratings may outperform higher rated ABEC bearings in specific applications.

Conclusion

Emerson Bearing has been distributing ball and roller bearings for more than half a century for both U.S. and international buyers. We specialize in crafting application-specific bearings to ensure our products perform as required for customers in any industry.

For more information on bearing precision and ABEC ratings for your application, check out our blog post: Levels of Precision – Choose Wisely: How Fast Your Bearings Need to Go.